FA-XIS Series Food X-ray Inspection Systems: Precision Detection for Packaged Food Products

In the global packaged food industry, even a tiny foreign fragment (glass, stone, stainless steel) hidden inside sealed packs can trigger $1M+ recalls, erode consumer trust, and fail strict regulatory audits (e.g., FDA, EU HACCP). For Indonesian packaged snack producer Crispy Treats—a supplier of sealed rice cracker packs to 3,000+ convenience stores across Southeast Asia—this risk became a pressing issue: their legacy metal detectors missed 0.8mm glass shards in foil-lined snack packs, leading to 3 customer complaints in 2024. The solution? Shanghai Fanchi-tech Machinery Co., Ltd.’s FA-XIS Series Food X-ray Inspection Systems (the equipment shown in our production floor imagery) — a range of high-precision systems purpose-built for the unique needs of sealed packaged food workflows.

Customer Success: Crispy Treats Secures Sealed Rice Cracker Packs

Crispy Treats faced two critical pain points specific to their packaged snack production:

- Metal detectors could not penetrate their foil-lined packaging to identify non-metallic contaminants (e.g., glass bits from mixing equipment).

- Their 250×150mm sealed snack packs outgrew smaller inspection tools, forcing manual re-checks that slowed packaging line throughput.

“After testing Fanchi-tech’s FA-XIS5025 model, we saw immediate results,” says Crispy Treats’ Quality Director, Lina Sutanto. “It easily accommodated our sealed, foil-lined packs, and flagged a 0.3mm stainless steel fragment and a 1.0mm glass bead in our first test batch—neither of which our metal detector could catch through the packaging. We haven’t had a single contamination issue with our sealed packs since installation.”

Since deploying 2 FA-XIS5025 units:

- Crispy Treats achieved 100% compliance with Indonesian Food and Drug Authority (BPOM) standards for packaged snacks.

- Cut foreign-body-related customer complaints to 0 (down from 3/quarter).

- Reduced packaging line downtime from 2 hours/week (manual re-inspections) to 15 minutes/week.

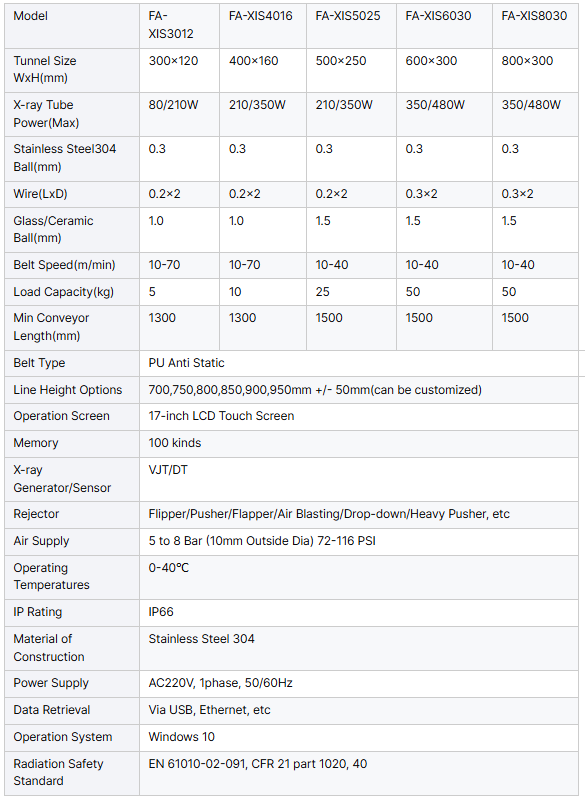

FA-XIS Series: Engineered for Packaged Food Production (Aligned with Our Specs & Imagery)

Our FA-XIS Series (shown in the workshop image—note the 17-inch touchscreen, 304 stainless steel housing, and mobile caster base) is tailored to address the unique challenges of sealed packaged food:

Core Advantages for Packaged Food

- Packaging-Penetrating Detection Precision:

The series reliably detects micro-contaminants through all common packaged food materials (foil, plastic, cardboard, or laminated films):Adaptable to Diverse Packaged Formats:

- 0.3mm stainless steel balls (from equipment wear, e.g., mixer blades)

- 0.2×2mm metal wire fragments

- 1.0–1.5mm glass/ceramic bits (non-metallic hazards hidden in sealed packs)

-

Configured to fit sealed packaged goods of all sizes—from small spice sachets to large frozen meal boxes. Load capacities (5kg to 50kg) and adjustable belt speeds (10–70m/min) sync seamlessly with high-throughput packaging lines.

- Hygienic, Packaged-Line Friendly Design:Compliance for Packaged Food Exports:

- 17-inch LCD touchscreen (Windows 10 OS) stores 100+ product profiles (for different pack sizes/formats), cutting packaging line changeover time.

- IP66-rated 304 stainless steel housing: Resists high-pressure washdowns (critical for hygienic packaged food environments) and meets FDA food contact regulations.

- Configurable rejectors (flipper, pusher, air blasting) remove contaminated sealed packs without disrupting continuous packaging workflows.

-

Meets strict global standards for packaged food: EN 61010-2-091 (equipment safety), CFR 21 part 1020.40 (radiation safety), and EU HACCP requirements—eliminating compliance barriers for export-focused packaged food brands.

Why Fanchi-tech for Packaged Food X-ray Inspection?

For producers like Crispy Treats, we deliver more than equipment:

- Packaging Line Integration: Our team adjusts line height (700–950mm, ±50mm) to fit your existing packaged food production layout—no costly retooling needed.

- On-Site Packaged Product Testing: We validate the system with your actual sealed packs (e.g., foil-lined snacks, cardboard frozen meal boxes) to confirm detection accuracy.

- Packaged Food Compliance Docs: Full certification packages (CE, FDA, BPOM) are provided ready for customer or regulatory audits of sealed products.

Take the Next Step: Secure Your Packaged Food Lines

Don’t let hidden contaminants risk your sealed packaged food brand. Contact Kerry Wang (Food Industry Specialist) to schedule a free virtual demo of the FA-XIS Series—we’ll test your sealed product samples (free of charge) to match you with the ideal configuration.

Shanghai Fanchi-tech Machinery Co., Ltd.

- Email: fanchitech@outlook.com

- Website: www.fanchitechnology.com

Post time: Dec-10-2025