Low MOQ for Automatic X-Ray Inspection - Fanchi-tech Multi-sorting Checkweigher – Fanchi-tech

Low MOQ for Automatic X-Ray Inspection - Fanchi-tech Multi-sorting Checkweigher – Fanchi-tech Detail:

Introduction&Application

FA-MCW series Multi-sorting Checkweigher has been widely applied in fish and shrimp and a variety of fresh seafood, poultry meat processing, automotive hydraulic attachments classification, the daily necessities weight sorting packing industries, etc. With a Fanchi-tech multi-sorting checkweigher customized to your specifications, you can depend on accurate weight control, maximized efficiency, and consistent product throughput, even in rugged industrial environments.

Product Highlights

1.Maximum 12 weighing/sorting stages.

2.Excellent processing and weighing speed by FPGA hardware filter with intelligent algorithms.

3.Automatic parameter setting by intelligent product sampling.

4.Ultra-fast dynamic weight tracking and automatic compensation technology to effectively improve the weighing stability.

5.Easy operation by friendly touch screen HMI.

6.Storage of 100 product programs.

7.High capacity operation statistic record with USB data output.

8.High precision structural components and stainless steel 304 frame by CNC tooling.

Key Components

● German HBM high speed load cell

● Japanese Oriental motor

● Danish Danfoss frequency converter

● Japanese Omron Optic sensors

● French Schneider Electric Unit

● US Gates synchronous belt

● Japanese SMC pneumatic unit

● Weinview industrial touch screen

Technical Specification

|

Model |

FA-MCW160 |

FA-MCW230 |

FA-MCW300 |

|

Detecting Range |

10~1000g |

10~1000g |

10~4000g |

|

Scale Interval |

0.1g |

0.1g |

0.1g |

|

Detecting Accuracy |

±0.1g |

±0.2g |

±0.3g |

|

Detecting Speed |

150pcs/min |

150pcs/min |

100pcs/min |

|

Weigher Size(W*L mm) |

160×300 |

230×450 |

300×550 |

|

Material of Construction |

Stainless Steel 304 |

||

|

Belt Type |

PU Anti Static |

||

|

Line Height Options |

600,650,700,750,800,850,900mm +/- 50mm(can be customized) |

||

|

Operation Screen |

7-inch LCD Touch Screen |

||

|

Memory |

100 kinds |

||

|

Weigh Sensor |

HBM high accuracy load cell |

||

|

Rejector |

Air Blasting/Pusher/Flipper, etc |

||

|

Air Supply |

5 to 8 Bar (10mm Outside Dia) 72-116 PSI |

||

|

Operating Temperatures |

0-40℃ |

||

|

Self-diagnosis |

Zero error, photosensor error, setting error, products too close error. |

||

|

Other Standard Accessories |

Windshield cover(colorless and clear), photo sensor; |

||

|

Power Supply |

AC110/220V, 1phase, 50/60Hz |

||

|

Data Retrieval |

Via USB(standard), Ethernet is optional |

||

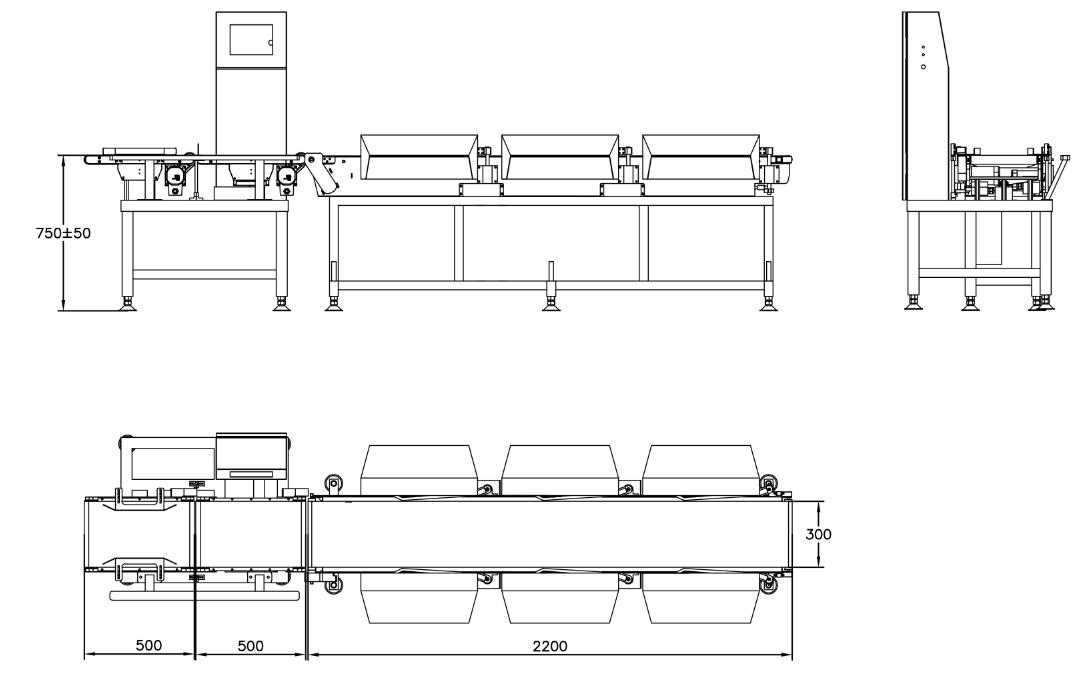

Size Layout

Product detail pictures:

Related Product Guide:

SO KUle

Our business puts emphasis over the administration, the introduction of talented staff, plus the construction of team building, attempting hard to boost the standard and liability consciousness of personnel customers. Our corporation successfully attained IS9001 Certification and European CE Certification of Low MOQ for Automatic X-Ray Inspection - Fanchi-tech Multi-sorting Checkweigher – Fanchi-tech , The product will supply to all over the world, such as: Los Angeles, Melbourne, Amman, Looking forward, we will keep pace with the times, continuing to create new products. With our strong research team, advanced production facilities, scientific management and top services, we will supply high quality products to our customers worldwide. We sincerely invite you to be our business partners for mutual benefits.

Problems can be quickly and effectively resolved, it is worth to be trust and working together.