Fanchi-Tech Dual-Beam X-Ray Inspection System For Canned Products

Introduction&Application

Fanchi-Tech Dual-Beam X-Ray Inspection System For Canned Products

Fanchi-tech Dual-beam x-ray system is specially designed for the complicated detection of glass particles in glass or plastic or metal containers. It also detects unwanted foreign objects such as metal, stones, ceramics or plastic with high density in the product. The FA-XIS1625D devices use a scanning hight up to 250 mm with a straight product tunnel for conveyor speed up to 70m/min.The hygienic design with protection type IP66 for the product tunnel makes it particularly suitable for all companies and industries that have to ensure high hygiene standards.

Product Highlights

-

Raised bottoms:

-

The dual beam X-ray inspection system prevents blind areas when inspecting jars.

-

Large thin foreign bodies:Reliable detection of a thin glass sliver, most likely not detected with a single beam system.

-

Hygienic design, follow EHEDG principles featuring sloped surfaces and curved edges allowing easy inspection and cleaning, resulting in considerable time and cost savings

-

Combining high detection sensitivity with low power consumption

-

A wide range of standard possibilities for ensuring product integrity and quality, including:

- Checking completeness;

- Determining product mass;

- Determining compartment mass

-

Algorithms are designed to help improve product imaging. This includes image contrasting; Mask, for masking out part of the product such as packaging clips; and Box Remover that blanks out the edges of a packaging box or container to inspect only the contents.

Technical Specification

| Model | FA-XIS1625S | FA-XIS1625D |

| Tunnel Size WxH(mm) | 160x280 | 160x280 |

| X-ray Tube Power(Max) | Single Side Beam:80Kv, 350/480W | Dual-beam:80Kv, 350/480W |

| Stainless Steel304 Ball(mm) | 0.3 | 0.3 |

| Wire(LxD) | 0.3x2 | 0.3x2 |

| Glass/Ceramic Ball(mm) | 1.5 | 1.5 |

| Belt Speed(m/min) | 10-90 | 10-90 |

| Load Capacity(kg) | 25 | 25 |

| Min Conveyor Length(mm) | 3300 | 4000 |

| Belt Type | PU Anti Static | |

| Line Height Options | 700,750,800,850,900,950mm +/- 50mm(can be customized) | |

| Operation Screen | 17-inch LCD Touch Screen | |

| Memory | 100 kinds | |

| X-ray Generator/Sensor | VJT/DT | |

| Rejector | Air blast rejector or Pusher, etc | |

| Air Supply | 5 to 8 Bar (10mm Outside Dia) 72-116 PSI | |

| Operating Temperatures | 0-40℃ | |

| IP Rating | IP66 for Conveying Part | |

| Material of Construction | Stainless Steel 304 | |

| Power Supply | AC220V, 1phase, 50/60Hz | |

| Data Retrieval | Via USB, Ethernet, etc | |

| Operation System | Windows 10 | |

| Radiation Safety Standard | EN 61010-02-091, FDA CFR 21 part 1020, 40 | |

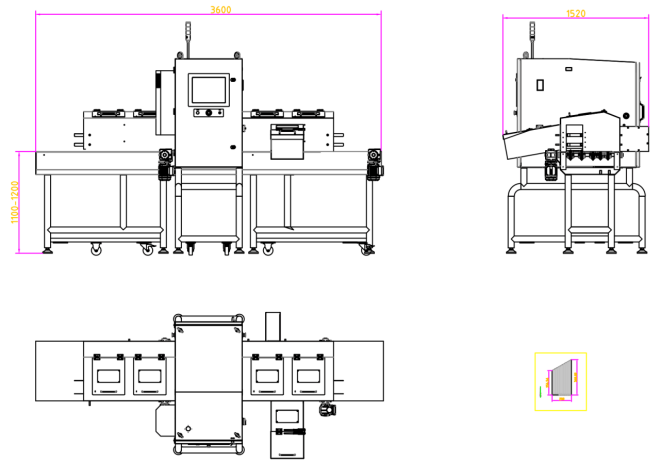

Size Layout